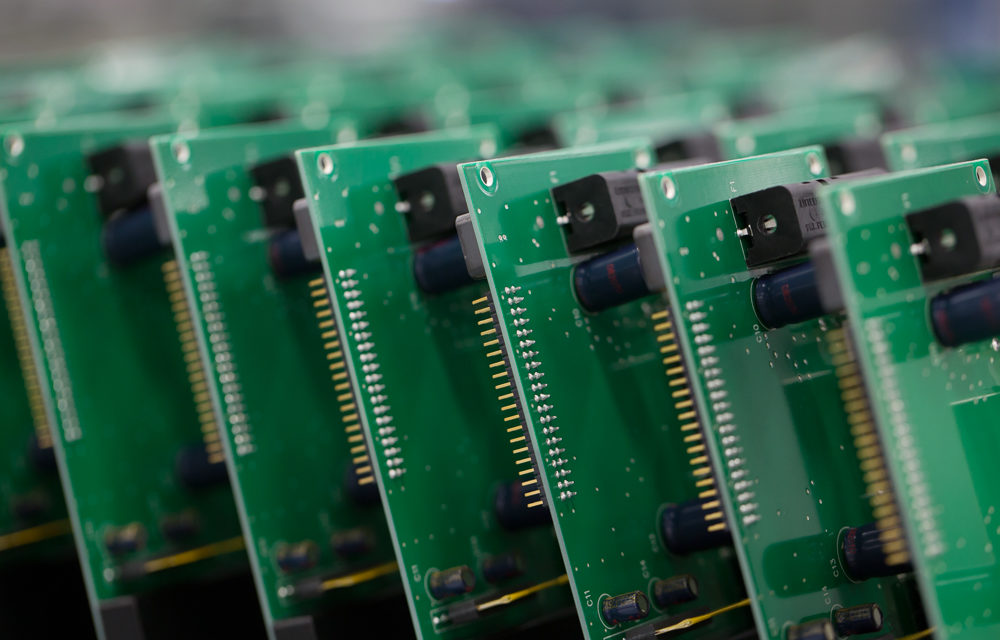

Over the last decade, there has been a great push to move the assembly of printed circuit boards from the United States to Asia and Eastern Europe to reduce cost. However, this may not make sense for a low to medium volume product, as there are many hidden costs with manufacturing off shore.

The end customer must take the following into account:

- Labor cost vs. material cost

- Cost of shipping the product, including duties

- Language barrier

- Time zone difference

- Time to implement product changes (ECO’s)

- Distance between the end customer and the manufacturing site

There are significant advantages to sourcing a product with a local, highly skilled contract manufacturer, like Columbia Tech, with a strong supply chain since labor is a small percentage of the total cost of a complex product that has a high percentage of its parts equipment-placed. These advantages include:

- Flexibility to build small runs of product with significant change traffic

- The ability to meet with the contract manufacturer as needed, without significant cost and planning

- Clear, concise communications with production management and staff, without the need of a translator

- Reduced cycle times between product completion and receipt, without significant shipping costs

The End Customer must take all of the previously listed items into account when deciding whether or not to outsource printed circuit board assembly to other markets, as all items can have significant implications which will affect bottom line profitability.

Phil Provencal

VP PCB Operations

Contact Columbia Tech today to discuss your organization's needs and aspirations. Columbia Tech can help you grow, thrive and profit.

Contact Columbia Tech today to discuss your organization's needs and aspirations. Columbia Tech can help you grow, thrive and profit.