By Vlad Krylov, Optical Engineering Manager

Optical systems are playing an ever-increasing role in consumer, medical, industrial, and communications industries. With optical component manufacturing being a very specialized industry, most of the optical and laser systems integrators deal with the tasks of specifying, procuring, inspecting, and assembling optics. The latter two tasks are concerned with the handling of optical components and require a particular set of skills, equipment and facilities.

Inspection of optical component properties, such as surface flatness, irregularity, or power; spectral transmittance or reflectance, requires equipment and facilities that can cost upward of $100K in capital investment – rarely justifiable for the optical component volumes that system integrators deal with. Therefore, establishing supplier relationships which rely on suppliers’ quality systems and their outgoing inspection is imperative to a lean optical system integration process.

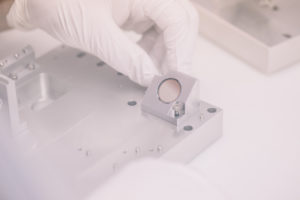

The exception to the general goal of relying on suppliers’ inspection capabilities is the in-house inspection of properties which may be affected during optical component integration. The most common would be a scratch-dig inspection allowing “fit for purpose” determination if the optic gets damaged during the assembly process due to mishandling.

The exception to the general goal of relying on suppliers’ inspection capabilities is the in-house inspection of properties which may be affected during optical component integration. The most common would be a scratch-dig inspection allowing “fit for purpose” determination if the optic gets damaged during the assembly process due to mishandling.

Cleanliness of optical components is a key performance characteristic of any optical system. Establishing appropriate cleanliness specification, receiving optics in clean condition, and maintaining that clean condition throughout the assembly process is always a better strategy than having a cleaning step as part of the assembly procedure or work instruction. While the knowledge of optics cleaning methods, appropriate tools, and labor force skilled in their application are a prerequisite for any manufacturer who deals with optics, cleaning of an optical component should be considered a re-work step requiring subsequent inspection before the optic is re-introduced into the manufacturing process flow.

Cogmedix manufactures and integrates thousands of optical and laser-based medical devices annually. This capacity is based on our lean and robust optical component acquisition and handling process throughout system integration.